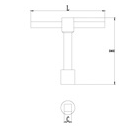

Non-sparking cylinder wrench all kinds No.1106

1.aluminum bronze&beryllium material

2.die forged processing

3.own factory

4.ISO9001 certification

Specification:

Composition:

Beryllium copper: GBEx ⅡC Be: 1.8% - 2.3% Ni: 0.2% - 0.5% Others: < 0.5% Cu: Rest Hardness: 35-40 HRC (HB283-365) Tensile Strength: 1117 N/mm2 ~ 1326 N/mm2 |

Aluminum bronze: GBEx ⅡB Al: 10% - 12% Ni: 4% - 6% Fe+Mn: < 5.8% Cu: Rest Hardness: 20-30 HRC (HB229-291) Tensile Strength: 782 N/mm2 ~ 989 N/mm2 |

Composition:

No-Sparking Tool Materials: Copper Beryllium Tools

When selecting the right alloy for your non-sparking, non-magnetic safety tools, you have two choices: copper beryllium tools or aluminum bronze tools.

1.Hardness copper beryllium with an HRC of 35-40.

2.Magnetic properties Beryllium copper tools have a more non-ferrous composition, so this equipment is safer for applications that require non-magnetic properties.

3.Composition:

Beryllium copper alloy tools: Be: 1.8-2.3%, Co + Ni: 0.4%, Other: 0.5%, Cu: Balance.

Beryllium copper: GBEx ⅡC Be: 1.8% - 2.3% Ni: 0.2% - 0.5% Others: < 0.5% Cu: Rest Hardness: 35-40 HRC (HB283-365) Tensile Strength: 1117 N/mm2 ~ 1326 N/mm2 |

Aluminum bronze: GBEx ⅡB Al: 10% - 12% Ni: 4% - 6% Fe+Mn: < 5.8% Cu: Rest Hardness: 20-30 HRC (HB229-291) Tensile Strength: 782 N/mm2 ~ 989 N/mm2 |

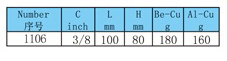

We have over 350 items, over 2000 specifications in Non-sparking Tools.All of tools are strictly in accordance with the DIN standard of Germany and national GB standard of China. Forged by a large friction pressing machine with one-time molding, our products enjoy a good quality.Under a perfect quality control system,our products have all been through a series of test from the material purchasing to end-product delivery,which ensure a 100% qualified rate before they are delivered out of the factory.

As a rising star of the Non-sparking Tools industry, the company obtained ISO9001 quality management certification and ISO14000 international environmental certification and OHSAS18000 occupational health certification. So that products are not only popular in China, but also exported to Europe and the United States, the Middle East, Southeast Asia and other places.

Forging Vs Casting

The Difference Between Casting & Forging

Casting is the process where metal is heated until molten. While in the molten or liquid state it is poured into a mold or vessel to create a desired shape.

Forging is the application of thermal and mechanical energy to steel billets or ingots to cause the material to change shape while in a solid state.

The advantages of forging include:

1.Generally tougher than casting.

2.Will handle impact better than castings

3.The nature of forging excludes the occurence of porosity, shrinkage, cavities and cold pour issues.

4.The tight grain structure of forgings making it mechanically strong. There is less need for expensive alloys to attain high strength components.

5.The tight grain structure offers great wear resistance without the need to make products “superhard” .

Quick Delivery and Proper Package

Sufficient stock make the order can be delivered timely.

Delivery Time: Order with less 100pcs,within 7 days.

Detailed Package: Each piece of non-sparking tools pack in a polythene bag, then some pack in cartons with different sizes depends on the quantity. We will make the package water-proof and shock-proof.

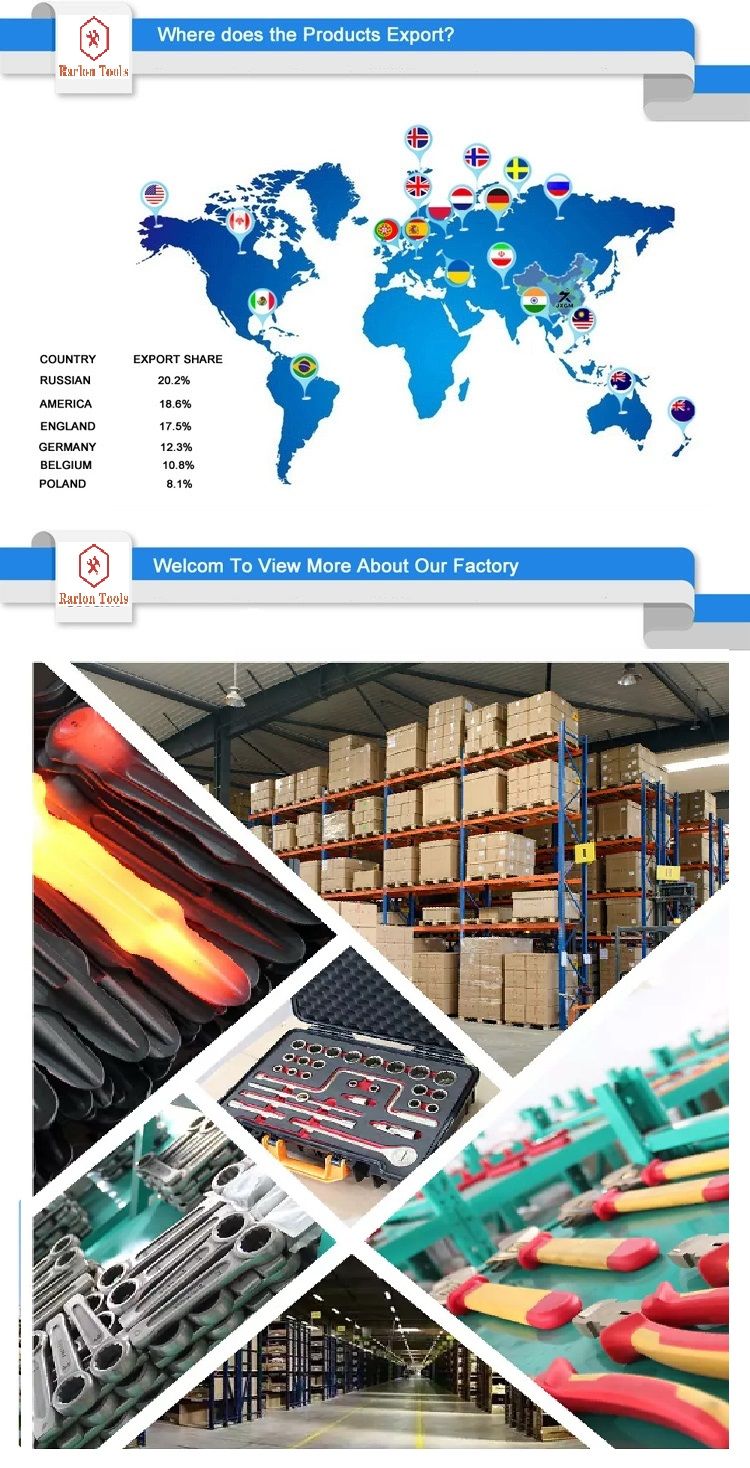

Our Production Workshop

We have more than 20 years experience in manufacturing Non-sparking Tools.Skilled workers and advanced equipments make our non-sparking tools have precise tolerance and high quality.

We can produce more than 5000000 pcs non-sparking tools per year. The main products include: Wrenches, Pliers, Screwdrivers, Hammers etc made from Beryllium copper and Aluminum bronze alloy.

FAQ

1.Are you factory?

Yes, we are factory which specialize in manufacturing non-sparking tools and special steel hand tools

2.Payment Terms?

LC/TT/DP

100% T/T in advance if the order under $1000.

3. How to contact?

Mobile:+86-155 304 66668 +86-150 2873 6829

Tel:+86-155 304 66668

Fax:+86-155 304 66668